Green Credentials

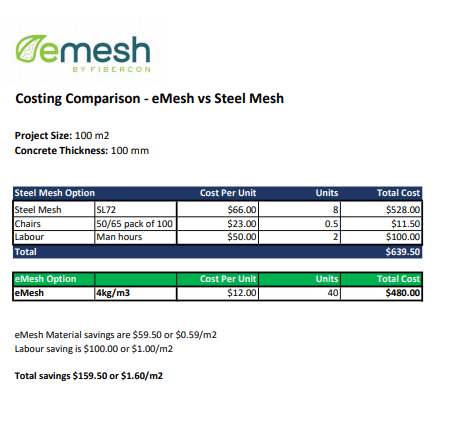

eMesh uses 100% recycled plastic fibres dispersed throughout concrete providing clients with a quality result and substantial environmental gains without adding cost to their projects

Scientists have tested the green credentials of eMesh, reporting a 90% saving on CO2 emissions and reduced fossil fuel usage compared to traditional steel mesh reinforcing. Further, the scientific findings behind the eMesh claims have been peer-reviewed by the prestigious Journal of Cleaner Production

Superior Technical Performance

The technical performance of eMesh is as good, if not better than, conventional steel mesh reinforced concrete. Clients using the product have reported superior post-crack performance

No corrosion issues in concrete reduces repair works

Steel mesh corrosion in concrete floors

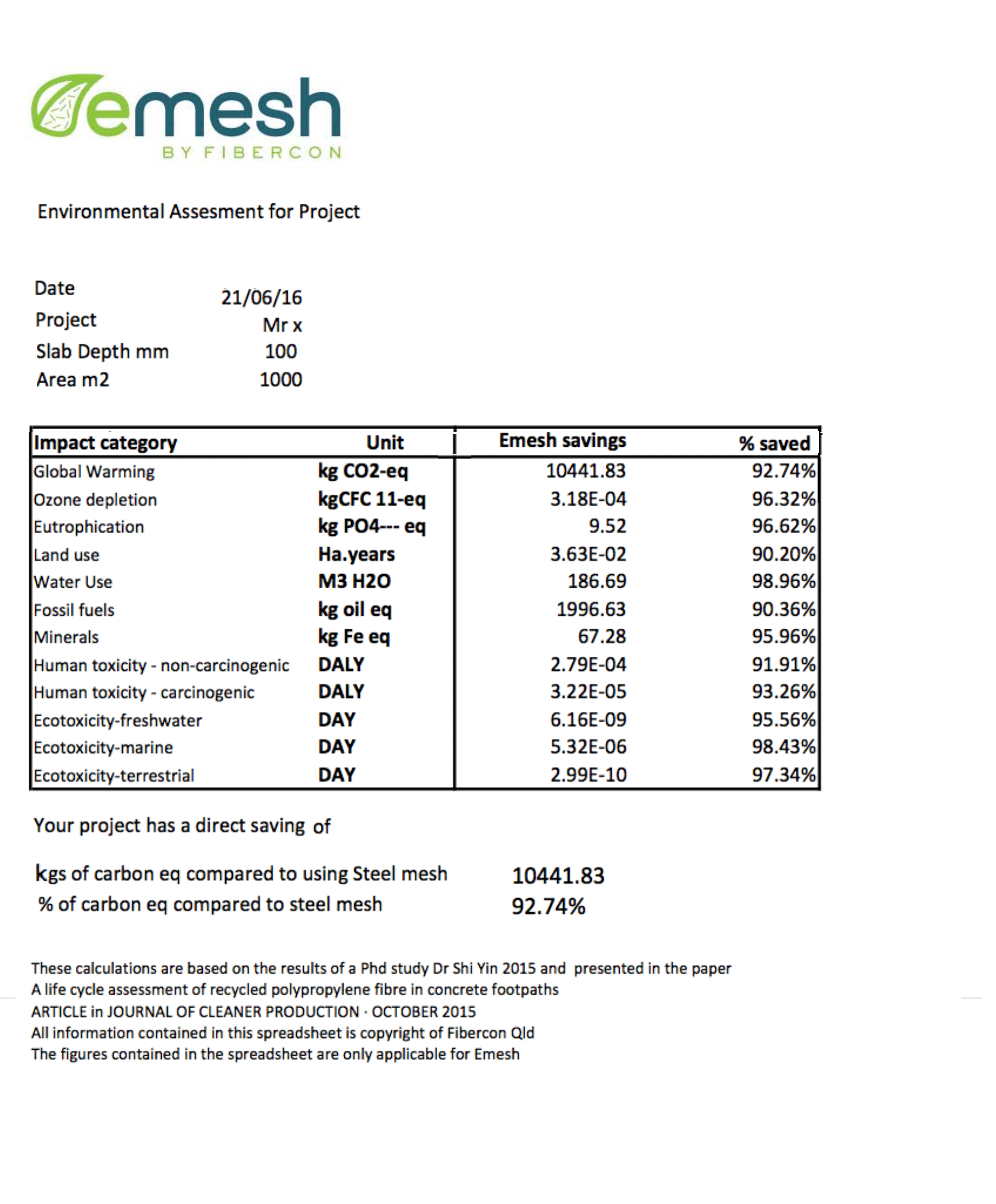

Environmental Assessment

The table below represents the total environmental benefits of using eMesh fibres instead of SL72 mesh. Dr Shi Yin conducted an exhaustive LCA using the most advanced software Simapro and the above results are from this study. As can be seen this project saves over 10 tons of CO2 emissions compared to using steel mesh – a great outcome for the project and the environment.

Using eMesh shows a way to reduce the environmental impact our projects have in all affected areas from Carbon emissions to Carcinogens that cause cancer.